Product Description

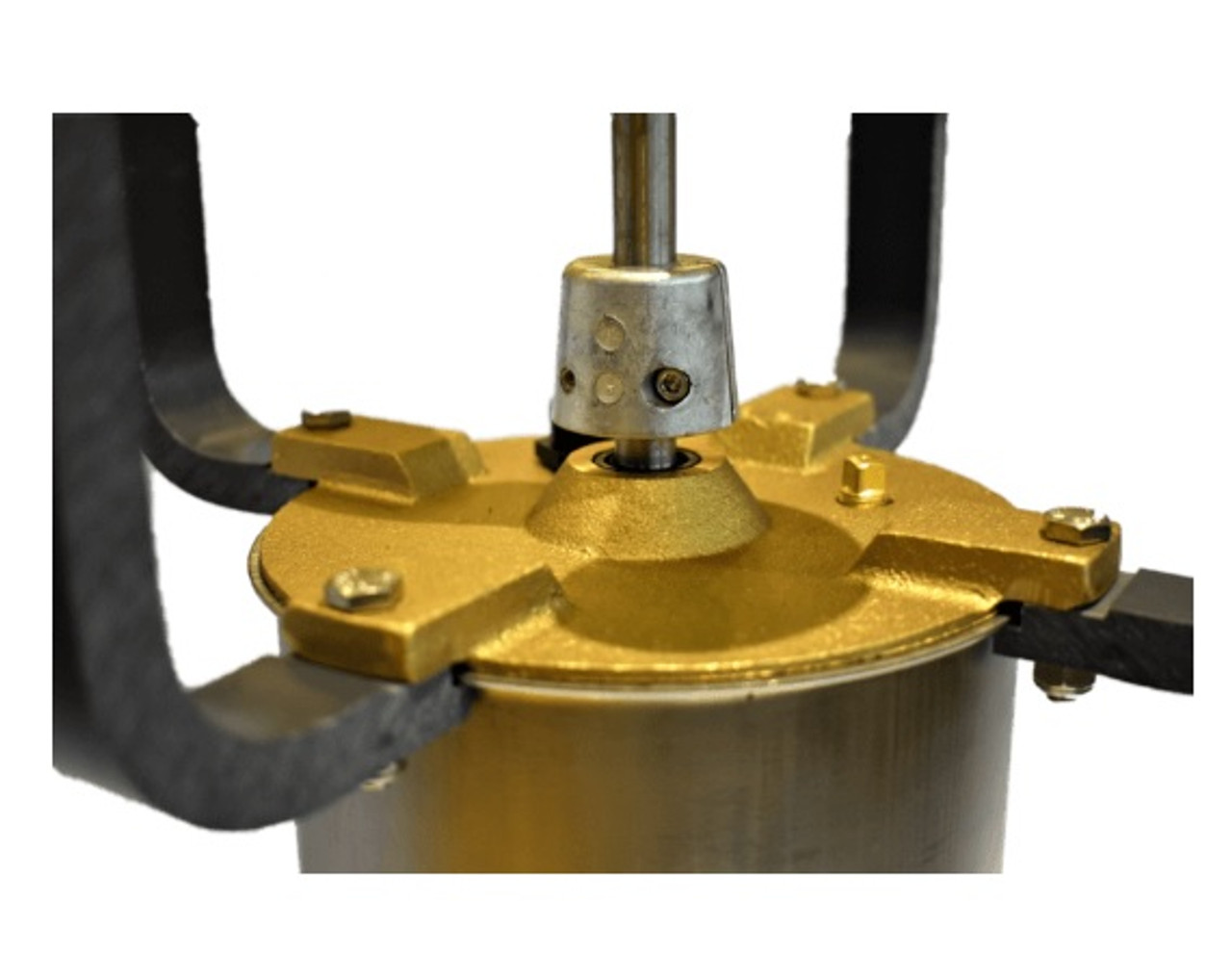

Bearon Surface Aerators Sacrificial Anode / Electrolysis Kit for Salt/Brackish Water

Aluminum Alloy Anodes are a sacrificial metal with one purpose; to prevent and deter corrosion of underwater metals in the Ice Eater and other off-brand de-icers.

Inspect the Aluminum Anode periodically (at least every 2-3 months) for deterioration and/or corrosion.

You must replace the Aluminum Anodes when it has been reduced to half of the original size (original size – 1.5″ Diamater x 1.25″ Tall).

Failure to operate the Ice Eater with the anode could result in deterioration and contamination of the Ice Eater metals and may void your warranty.

Aluminum is Better than Zinc:

- Aluminum Anodes are the best choice of sacrificial anodes for all water types.

- Proven to last longer than Zinc Anodes due to increased capacity.

- Zinc Anodes, when used in fresh or brackish water, are prone to developing a calcareous coating. This layer of calcium carbonate appears whitish and essentially puts a zinc anode to sleep. Many watermen mistakenly perceive these especially “long-lived” zinc anodes to be effective.

- Unlike Zinc Anodes, Aluminum Anodes have zero cadmium in the alloy, making Aluminum Anodes environmentally friendly and suitable for all uses.

Aluminum Alloy Anodes are manufactured to meet or exceed US Military Specification MIL-A-24779(SH)

Size Guide:

- One size fits all Ice Eaters and all off-brand de-icers with a 1/2″ shaft.

Installation Guide:

- Allen wrench included with Aluminum Anode.